AI Without Workflow Is Just a Dashboard: Bridging the Gap Between Video Analytics and ROI in Manufacturing

Introduction: Why Smart Factories Still Run on Manual Decisions

Manufacturing plants are rapidly adopting AI video analytics to improve:

● Safety compliance

● Production efficiency

● Quality inspection

● Asset utilization

● Safety compliance

● Production efficiency

● Quality inspection

● Asset utilization

Cameras are installed. AI models are deployed. Dashboards light up with insights.

Yet in most factories, daily operations remain unchanged.

● Line stoppages still require manual escalation

● Safety violations still depend on supervisors noticing alerts.

● Quality defects are detected, but corrective actions are delayed.

The reason is simple but uncomfortable:

AI video analytics in manufacturing often stops at dashboards, not decisions.

And dashboards don’t run factories; workflows do.

The Manufacturing Reality: Insights Without Action Don’t Improve Throughput

Most manufacturing video analytics systems answer only one question:

“What happened?”

But real factories need answers to:

● Does this affect throughput or OEE?

● Does this violate SOPs or safety norms?

● Should the line stop or continue?

● Who must act immediately?

● What corrective workflow should trigger?

Without these answers, AI remains observational, not operational.

● Line stoppages still require manual escalation

● Safety violations still depend on supervisors noticing alerts.

● Quality defects are detected, but corrective actions are delayed.

The reason is simple but uncomfortable:

AI video analytics in manufacturing often stops at dashboards, not decisions.

And dashboards don’t run factories; workflows do.

The Manufacturing Reality: Insights Without Action Don’t Improve Throughput

Most manufacturing video analytics systems answer only one question:

“What happened?”

But real factories need answers to:

● Does this affect throughput or OEE?

● Does this violate SOPs or safety norms?

● Should the line stop or continue?

● Who must act immediately?

● What corrective workflow should trigger?

Without these answers, AI remains observational, not operational.

Why Manufacturing AI Video Analytics Fails to Deliver ROI

1. AI Is Not Integrated into Plant Workflows

In many plants, AI video analytics operates separately from core manufacturing systems such as

● MES

● ERP

● CMMS

● Quality Management Systems (QMS)

● Safety and incident platforms

This disconnect leads to:

● Operators switching between multiple systems

● Manual interpretation of alerts

● Delayed response to critical events

If AI does not trigger workflows, it does not change outcomes.

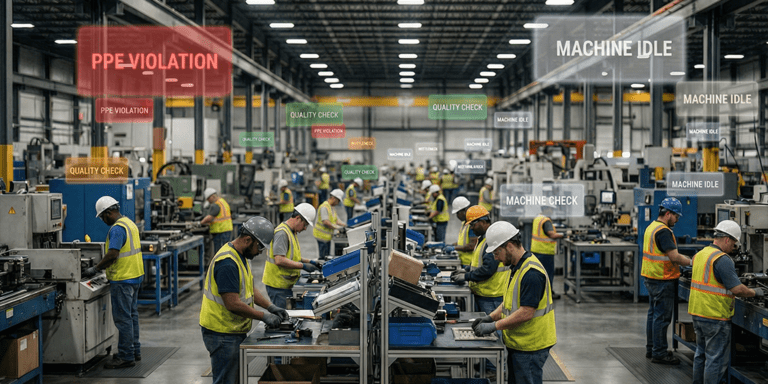

2. Line-Level Decisions Are Still Manual

Common manufacturing use cases include:

● PPE violations

● Incorrect assembly steps

● Unauthorized access to machines

● Bottleneck formation on production lines

AI can detect these events, but:

● Line supervisors still decide manually.

● Escalations vary by shift and individual.

● Actions lack consistency

This variability kills repeatability, and repeatability is the foundation of manufacturing ROI.

3. Alert Fatigue on the Shop Floor

Manufacturing environments are noisy both physically and digitally.

When AI systems:

● Trigger excessive alerts

● Lack of context (critical vs. non-critical)

● Ignore production priorities

Operators start ignoring them. Over time, AI alerts become background noise, not decision signals.

4. No Closed-Loop Learning from Production Outcomes

Most AI video analytics systems follow this flow:

Camera → AI Model → Alert → Dashboard

What’s missing:

● Was the alert valid?

● Was action taken?

● Did it reduce downtime, defects, or safety incidents?

● Should the decision logic improve next time?

Without feedback loops, AI performance plateaus or degrades in real manufacturing conditions.

In many plants, AI video analytics operates separately from core manufacturing systems such as

● MES

● ERP

● CMMS

● Quality Management Systems (QMS)

● Safety and incident platforms

This disconnect leads to:

● Operators switching between multiple systems

● Manual interpretation of alerts

● Delayed response to critical events

If AI does not trigger workflows, it does not change outcomes.

2. Line-Level Decisions Are Still Manual

Common manufacturing use cases include:

● PPE violations

● Incorrect assembly steps

● Unauthorized access to machines

● Bottleneck formation on production lines

AI can detect these events, but:

● Line supervisors still decide manually.

● Escalations vary by shift and individual.

● Actions lack consistency

This variability kills repeatability, and repeatability is the foundation of manufacturing ROI.

3. Alert Fatigue on the Shop Floor

Manufacturing environments are noisy both physically and digitally.

When AI systems:

● Trigger excessive alerts

● Lack of context (critical vs. non-critical)

● Ignore production priorities

Operators start ignoring them. Over time, AI alerts become background noise, not decision signals.

4. No Closed-Loop Learning from Production Outcomes

Most AI video analytics systems follow this flow:

Camera → AI Model → Alert → Dashboard

What’s missing:

● Was the alert valid?

● Was action taken?

● Did it reduce downtime, defects, or safety incidents?

● Should the decision logic improve next time?

Without feedback loops, AI performance plateaus or degrades in real manufacturing conditions.

Why Dashboards are the Wrong Abstraction for Manufacturing

Manufacturing does not run on dashboards.

It runs on:

● Standard Operating Procedures (SOPs)

● Escalation matrices

● Shift-based ownership

● SLAs and response timelines

● Corrective and Preventive Actions (CAPA)

If AI does not:

● Trigger SOPs automatically

● Assign clear responsibility

● Enforce timelines

● Learn from execution outcomes

It cannot deliver sustained ROI.

What Actually Works: Workflow-Driven AI in Manufacturing

Plants that succeed with AI video analytics design systems that answer:

● What exactly happened on the production line?

● Does this impact safety, quality, or throughput?

● Which SOP or rule applies?

● Who must act as operator, supervisor, or maintenance?

● What happens if action is delayed?

This is where AI shifts from monitoring operations to running operations

It runs on:

● Standard Operating Procedures (SOPs)

● Escalation matrices

● Shift-based ownership

● SLAs and response timelines

● Corrective and Preventive Actions (CAPA)

If AI does not:

● Trigger SOPs automatically

● Assign clear responsibility

● Enforce timelines

● Learn from execution outcomes

It cannot deliver sustained ROI.

What Actually Works: Workflow-Driven AI in Manufacturing

Plants that succeed with AI video analytics design systems that answer:

● What exactly happened on the production line?

● Does this impact safety, quality, or throughput?

● Which SOP or rule applies?

● Who must act as operator, supervisor, or maintenance?

● What happens if action is delayed?

This is where AI shifts from monitoring operations to running operations

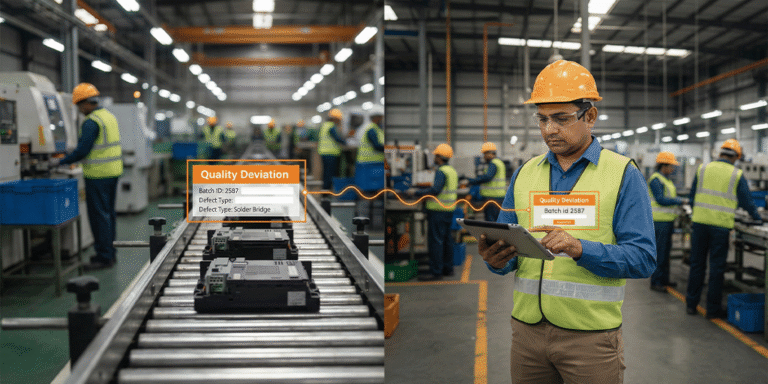

How Intozi Stands Out in Manufacturing AI Video Analytics

1. Workflow-First, Plant-Centric Design

Intozi builds AI video analytics with a workflow-first approach, designed specifically for manufacturing plants.

Instead of static dashboards, Intozi enables systems that:

● Trigger maintenance or quality tickets

● Escalate safety violations automatically

● Notify supervisors with clear context

● Integrate seamlessly with MES, CMMS, and plant systems

AI becomes part of daily plant execution, not just reporting.

2. Context-Aware Vision, Not Generic Detection

Manufacturing environments constantly change:

● Shifts and manpower

● Product variants

● Line layouts and configurations

Intozi’s AI understands context, not just objects:

● Which product is currently running?

● Which SOP applies?

● Is this deviation acceptable or critical?

This reduces false alerts and improves decision accuracy.

3. Closed-Loop Learning from Plant Actions

Intozi captures real execution data, including:

● Actions taken by operators and supervisors

● Resolution time

● Effectiveness of corrective actions

This closed-loop feedback continuously improves:

● Detection logic

● Alert relevance

● Decision quality over time

Intozi builds AI video analytics with a workflow-first approach, designed specifically for manufacturing plants.

Instead of static dashboards, Intozi enables systems that:

● Trigger maintenance or quality tickets

● Escalate safety violations automatically

● Notify supervisors with clear context

● Integrate seamlessly with MES, CMMS, and plant systems

AI becomes part of daily plant execution, not just reporting.

2. Context-Aware Vision, Not Generic Detection

Manufacturing environments constantly change:

● Shifts and manpower

● Product variants

● Line layouts and configurations

Intozi’s AI understands context, not just objects:

● Which product is currently running?

● Which SOP applies?

● Is this deviation acceptable or critical?

This reduces false alerts and improves decision accuracy.

3. Closed-Loop Learning from Plant Actions

Intozi captures real execution data, including:

● Actions taken by operators and supervisors

● Resolution time

● Effectiveness of corrective actions

This closed-loop feedback continuously improves:

● Detection logic

● Alert relevance

● Decision quality over time

Conclusion: AI Creates Value Only When It Takes Action

AI video analytics doesn’t fail in manufacturing because the technology is weak.

Cameras work. Models detect events. Data is available.

The real issue is that AI often stops at dashboards

Cameras work. Models detect events. Data is available.

The real issue is that AI often stops at dashboards

AI without workflows is just a dashboard, and dashboards don’t run factories.

Manufacturing improves only when insights lead to clear actions: safety issues are escalated, quality problems trigger fixes, and line issues are handled quickly and consistently. Seeing problems is not enough acting on them is what improves OEE and results.

With a workflow-driven approach, Intozi helps factories turn AI insights into real, everyday action and real operational ROI.

Turning AI Alerts into Real Results

Intozi does more than just spot problems, it helps you fix them. Our workflow orchestration turns simple AI alerts into clear, enforceable actions. Instead of just getting a notification, your team can automatically trigger line stops, alert supervisors, or track repairs based on how urgent the situation is. This turns raw data into a smart, step-by-step plan that keeps your plant running smoothly and consistently.

Security You Can Trust

We know that factory video is sensitive, so we built Intozi with “security-first” thinking. Your data is protected by enterprise-grade encryption and strict access controls, ensuring only the right people see what they need to. Whether you keep your data on-site or in the cloud, we use privacy masking and smart storage rules to meet global safety standards. With Intozi, you can grow your AI capabilities across every shift and location without ever risking your team’s privacy.

Manufacturing improves only when insights lead to clear actions: safety issues are escalated, quality problems trigger fixes, and line issues are handled quickly and consistently. Seeing problems is not enough acting on them is what improves OEE and results.

With a workflow-driven approach, Intozi helps factories turn AI insights into real, everyday action and real operational ROI.

Turning AI Alerts into Real Results

Intozi does more than just spot problems, it helps you fix them. Our workflow orchestration turns simple AI alerts into clear, enforceable actions. Instead of just getting a notification, your team can automatically trigger line stops, alert supervisors, or track repairs based on how urgent the situation is. This turns raw data into a smart, step-by-step plan that keeps your plant running smoothly and consistently.

Security You Can Trust

We know that factory video is sensitive, so we built Intozi with “security-first” thinking. Your data is protected by enterprise-grade encryption and strict access controls, ensuring only the right people see what they need to. Whether you keep your data on-site or in the cloud, we use privacy masking and smart storage rules to meet global safety standards. With Intozi, you can grow your AI capabilities across every shift and location without ever risking your team’s privacy.

Post Views: 45